LCD Display

The HD4480 is a popular chipset used in all manner of small LCD displays. This page documents how to wire one up to the 6502 processor bus and some code to control it.

Bus interfacing

The electrical interface to the HD4480 is fairly 6502 friendly. There are 8

parallel data lines D[0…7] which are set by the HD4480 when reading data

from the display and read by the HD4480 when writing. There is a single register

select (RS) line which is low to indicate access to the control register(s) and

high to read/write data from the display itself. There is the usual R/W

line to indicate whether data is being read from or written to the display and

there is a display enable (E) line which is taken high to indicate to the

display that the values on the control/data lines are intended for it.

Reading data from the display is a relatively unsurprising affair:

- Set RS to indicate whether one is reading the busy flag/RAM address or reading data from the display.

- Set R/

Whigh. - Set E high.

- Read byte from D[0…7].

- Set E low.

Similarly, writing data to the display is straightforward:

- Set RS to indicate whether one is writing the control register or sending data.

- Set R/

Wlow. - Set byte on D[0…7].

- Set E high.

- Set E low.

This is very similar to the way the 6502 performs reads and writes. The subtlety

is in how the E signal is generated. If it is by some address line decoding,

which it is on Búri, then the E signal will change during φ1 which is

before the R/W and data lines are stable. This is easily fixed

by making E conditional on φ2 being high.

All of the displays I have can run at 2MHz and so no additional logic is needed if the 6502 is running at 2MHz or slower. Thankfully Búri is a 2MHz machine by design so I can stop here. I may need to re-visit the bus adapter at a later date if I move Búri to 4MHz or greater.

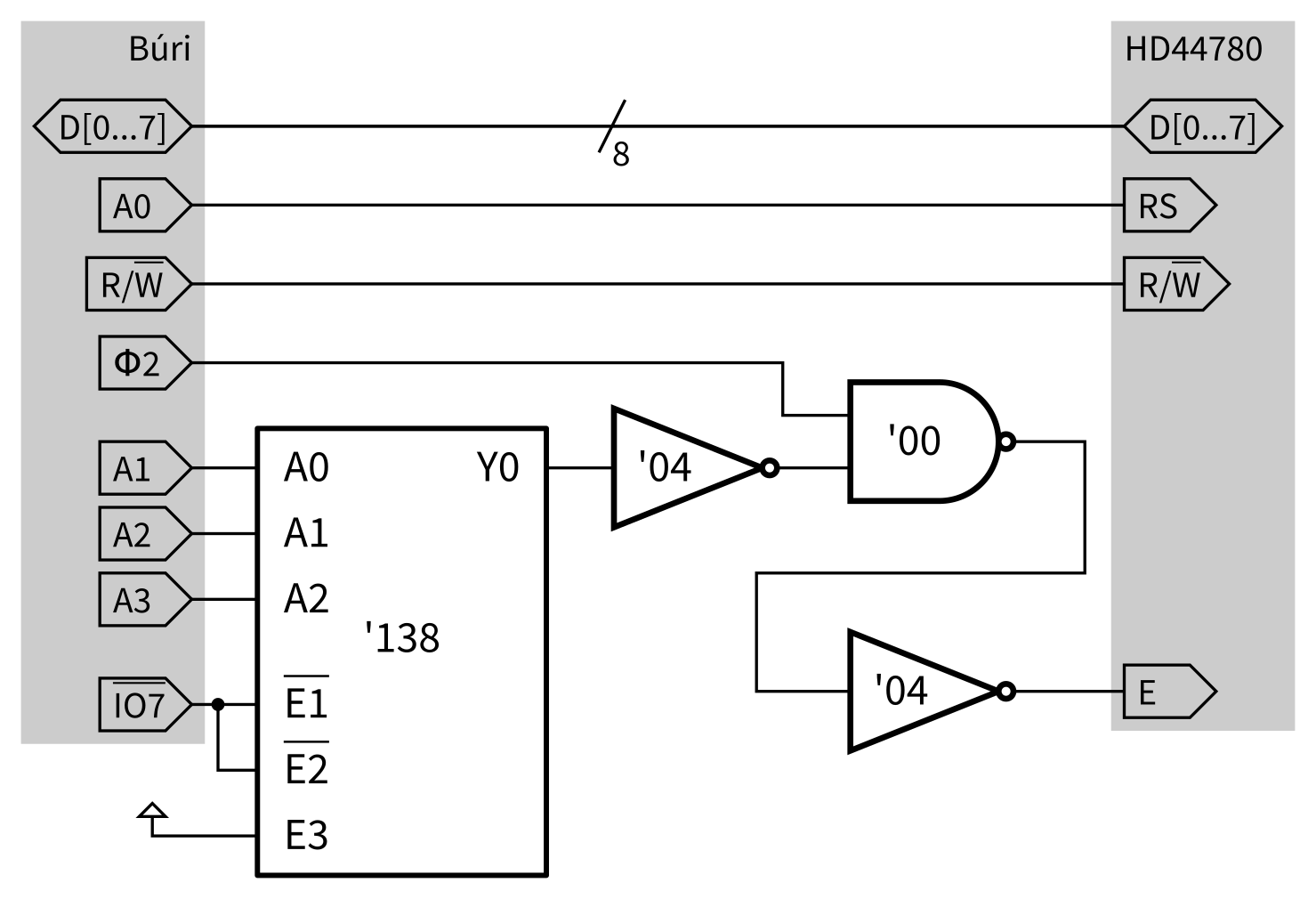

The complete bus logic is shown above. Here I’ve used a 74138 3-to-8 decoder to

select out the bottom two bytes from I/O area 7. (Búri will take IO7

low when bytes in the range $DFF0–$DFFF are accessed.) I use A0 as

register select and feed A[1…3] into the ‘138. I use a single 7400 NAND

gate to condition E on φ2 and a couple of 7404 NOT gates to flip some

signals around.

Testing

According to the datasheet, the display is controlled by writing to register 0 (which is at $DFF0 using the circuit above) and data is written to register 1 (exposed at $DFF1). The control bytes I need to send are:

- $38: enable 8-bit mode, 2 line display and 5×8 font.

- $0D: switch display on and have “blinking block”-style cursor.

- $01: clear display and move cursor to home position.

With the Búri OS, these steps can be performed via the poke command:

*poke dff0 38

*poke dff0 0d

*poke dff0 01Writing a message can be performed by writing character codes one at a time to $DFF1:

*poke dff1 48

*poke dff1 65

*poke dff1 6c

*poke dff1 6c

*poke dff1 6f

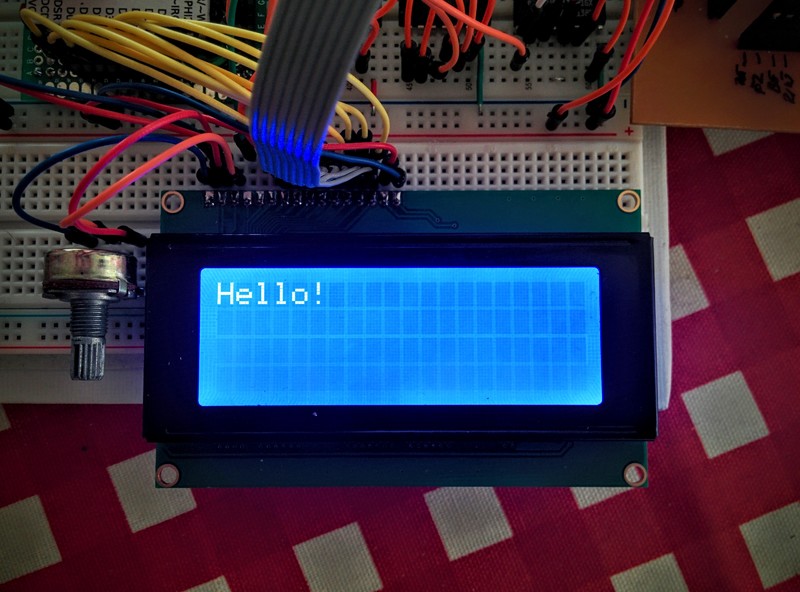

*poke dff1 21With the display connected to Búri, this is what I got after typing those commands:

Software

The LCD driver software is written in assembly. Most of the code is actually a series of macros to make writing routines more convenient. For example, the most basic functionality is writing data to and reading data from the display. We need to be careful to make sure the display is not busy before writing or reading data.

Basic I/O

Let’s start with some basic macros to read and write to the display.

; Location of the LCD registers in memory

LCD_R0 = $DFF0

LCD_R1 = LCD_R0 + 1

; Macro to wait for display to be ready. Sets A to the current address which

; will be written to by send_cmd.

.macro wait_rdy

.local loop

loop:

lda LCD_R0 ; read register 0

bmi loop ; loop if busy flag (bit 7) set

.endmacro

; Macro to write value in A to display. Reg should be LCD_R0 or LCD_R1 to

; determine if value is written to control or data register.

.macro write_dpy Reg

pha ; save A on stack

wait_rdy ; wait for display (corrupts A)

pla ; restore A

sta Reg ; write A

.endmacro

; Macro to read value into A from display. Reg should be LCD_R0 or LCD_R1 to

; determine if value is read from control or data register.

.macro read_dpy Reg

wait_rdy ; wait for display (corrupts A)

lda Reg ; read A

.endmacroNow we can define the various parameters of our display. My 20×4 display is arranged with a slightly odd ordering of lines with respect to display addresses. Rather than taking up space with code to compute the line offsets, it’s more space-efficient to just code a small lookup table:

LINE_LEN = 20 ; Length of a single line (characters)

LINE_COUNT = 4 ; Number of lines of text

; Lookup table for addresses corresponding to start of lines in display RAM.

.export line_addrs

line_addrs:

.byte #0, #64, #20, #84Cursor positioning

With the lookup table it’s easy enough to write a macro to calculate a display address from the corresponding x- and y-co-ordinates.

; Interpret X as characters from right (0-based) and Y as lines from top

; (0-based). Set A to the corresponding display address. If X and Y are outside

; of the defined area, the result is undefined.

.macro pos_to_dpy_addr

txa ; set A = X to begin with

clc

adc line_addrs, Y ; A += offset to start of line Y

.endmacroWe can use our macros to write a routine which sets the current cursor position based on the X and Y registers.

; Interpret X as characters from right (0-based) and Y as lines from top

; (0-based). Move the display cursor to this position. A is set to the value

; currently on the display at that position. If X and Y are outside of the

; defined area, the result is undefined.

.proc move_cursor

pos_to_dpy_addr ; X, Y => address stored in A

ora #$80 ; set high bit

write_dpy LCD_R0 ; write command byte to display

read_dpy LCD_R1 ; read contents

rts

.endprocOur OS will use the two zeropage locations lcdx and lcdy to store the

current cursor position. We can use these to write a “move right” routine.

.zeropage

; Reserve two bytes of zero page for LCD cursor.

lcdx: .res 1

lcdy: .res 1

.code

; Move the cursor to the right.

.proc move_cursor_right

pha ; save registers on stack

phx

phy

ldx lcdx ; load current position into X and Y

ldy lcdy

inx ; increment X

cpx #LINE_LEN ; compare X to line length

bcc set_pos ; X < line length, all done

ldx #0 ; move to next line

iny

cpy #LINE_COUNT ; compare Y to number of lines

bcc set_pos ; Y < number of lines, all done

ldy #0 ; reset back to upper left, see comment below

set_pos:

stx lcdx ; record new X

sty lcdy ; record new Y

jsr move_cursor ; move display cursor

exit:

pla ; restore registers from stack

plx

ply

rts

.endprocOur move right routine simple wraps the cursor at the bottom-right back to the

top-left. In the actual implementation, Y is set to LINE_COUNT-1 and the

display is scrolled up by copying data from lower lines to upper lines. The

scroll code isn’t very interesting. Similar move_cursor_left,

move_cursor_up and move_cursor_down routines can be written without too

much difficulty.

Writing characters to the display

With these support routines in place, writing a simple putc implementation

is fairly straightforward.

; Write ASCII character in A to the LCD screen and, if printable advance cursor

; to the right.

.export lcd_putc

.proc lcd_putc

cmp #$20 ; printable chars are >= $20

bcs printable ; if A >= $20 it's printable

cmp #$08 ; is A == ASCII backspace?

beq backspace

rts ; ignore all other chars (TODO: newline, etc)

backspace:

jsr move_cursor_left ; perform backspace...

rts ; ...and return

printable:

write_dpy LCD_R1 ; write character to display

jsr move_cursor_right ; advance cursor...

rts ; ...and return

.endprocThis function assumes that the LCD hardware cursor and lcdx, lcdy stay

in sync. We could explicitly set the cursor position before writing the

character but if you start writing directly to the LCD behind the OS’ back, you

deserve what you get!

Adding support for newline and carriage return is simply a case of

checking for ASCII $0A and $0D respectively then calling the appropriate

move_cursor_... routine.